Steel induction heating furnace(Rated temperature1600℃)

|

Model |

Rated capacity |

Rated power |

Rated frequency |

Power factor% |

Input voltage |

Melting rate(T/H) |

Power consumption (kw.h/T) |

Circulating water (T/H) |

Transformer capacity(KVA) |

|

HTSM-0.05T |

50KG |

100KW |

2500 HZ |

≥0.92 |

3Phase 380V 50Hz |

0.1 |

880 |

3 |

100 |

|

HTSM-0.1T |

100KG |

150kw |

1000 HZ |

≥0.92 |

3Phase 380V 50Hz |

0.21 |

780 |

5 |

160 |

|

HTSM-0.25T |

250KG |

200kw |

1000 HZ |

≥0.92 |

3Phase 380V 50Hz |

0.35 |

700 |

20 |

250 |

|

HTSM-0.35T |

350KG |

300KW |

1000 HZ |

≥0.92 |

3Phase 380V 50Hz |

0.38 |

700 |

30 |

315 |

|

HTSM-0.5T |

500KG |

400kw |

1000 HZ |

≥0.92 |

3Phase 380V 50Hz |

0.55 |

680 |

35 |

400 |

|

HTSM-0.75T |

750KG |

500kw |

1000 HZ |

≥0.92 |

3Phase 380V 50Hz |

0.77 |

670 |

50 |

500 |

|

HTSM-0.75TS |

750KG |

800KW |

1000 HZ |

≥0.92 |

3-phase 660V 50Hz |

1.13 |

600 |

80 |

800 |

|

HTSM-1T |

1T |

750kw |

1000 HZ |

≥0.92 |

3-phase 380V 50Hz |

1.0 |

650 |

60 |

800 |

|

HTSM-1TS |

1T |

1000kw |

700 HZ |

≥0.92 |

3-phase 660V 50Hz |

1.1 |

590 |

60 |

1000 |

|

HTSM-1.5T |

1.5T |

1000kw |

700 HZ |

≥0.92 |

3-phase 660V 50Hz |

1.5 |

590 |

100 |

1200 |

|

HTSM-1.5TS |

1.5T |

1200kw |

500 HZ |

≥0.92 |

6-phase 750V 50Hz |

2.0 |

580 |

100 |

1200(12 pulse) |

|

HTSM-2T |

2T |

1400kw |

500 HZ |

≥0.92 |

6-phase 750V 50Hz |

2.0 |

580 |

110 |

1600(12 pulse) |

|

HTSM-3T |

3T |

2000kw |

500 HZ |

≥0.92 |

6-phase 750V 50Hz |

2.8 |

570 |

160 |

2000(12 pulse) |

|

HTSM-5T |

5T |

2500kw |

500 HZ |

≥0.92 |

6-phase 750V 50Hz |

2.5 |

560 |

180 |

2500(12 pulse) |

|

HTSM-5TS |

5T |

3000kw |

300 HZ |

≥0.92 |

12-phase 950V 50Hz |

4.3 |

560 |

220 |

3150(12 pulse) |

|

HTSM-7T |

7T |

4000kw |

300 HZ |

≥0.92 |

12-phase 950V 50Hz |

7.0 |

550 |

250 |

2000(two pairs) |

|

HTSM-8T |

8T |

4500kw |

300 HZ |

≥0.92 |

12-phase 950V 50Hz |

7.5 |

550 |

250 |

2500(two pairs) |

|

HTSM-8TS |

8T |

5000kw |

300 HZ |

≥0.92 |

12-phase 950V 50Hz |

7.6 |

530 |

380 |

2500(two pairs) |

|

HTSM-10T |

10T |

5000kw |

300 HZ |

≥0.92 |

12-phase 950V 50Hz |

10.78 |

480 |

380 |

2500(two pairs) |

|

HTSM-10TS |

10T |

6000kw |

300 HZ |

≥0.92 |

12-phase 100V 50Hz |

9.58 |

480 |

120+160 |

3000(two pairs) |

|

HTSM-15T |

15T |

6000kw |

300 HZ |

≥0.92 |

24-phase 1000V 50Hz |

9.58 |

480 |

120+200 |

3000(two pairs) |

|

HTSM-20T |

20T |

6000kw |

300 HZ |

≥0.92 |

24-phase 1000V 50Hz |

9.58 |

480 |

120+250 |

3000(two pairs) |

Brief introduction:

01 medium frequency power supply is to convert ac power input from the grid into medium frequency power suitable for induction furnace. First, the three-phase or multiphase ac power input is rectified into DIRECT current, filtered by DC filter reactor, and then converted into single-phase medium frequency power through inverter.

02The frequency and output voltage can be adjusted according to the demand of the amount of molten steel in the furnace and the power size.

03 MF power supply is essentially a high-power inverter

04 The basic principle of induction furnace is a type of air core transformer, induction coil is equivalent to the primary winding of the transformer, and the metal within the crucible furnace charge is equivalent to the secondary winding of transformer (load).

05 when in the primary winding through the medium frequency current (500-2500 weeks/second or higher) on the role of the electromagnetic field under the influence, produce magnetic line secondary windings, Cause the charge induction potential, and vertical to the axis of the induction ring in the surface induced current (eddy current), so that the material itself heat the metal charge melting.

Series power supply:

The rectifier part of the series power supply is always fully open. Therefore, the dc voltage output is stable without reducing power factor and increasing harmonic content. The series inverter can output rated power in either cold state or hot state, with half charge or full charge. The series inverter always operates at rated output during the whole melting process. The rectifier voltage of series inverters is not controllable, and the power output can be changed by controlling the inverters, so the rectifier can supply power to two or more inverters at the same time, realizing double or multiple power supply of one power source. Two or multiple furnaces get the power at the same time, without any switching switch between the electric furnaces, in two or more electric furnaces, the power can be adjusted arbitrarily in the range of 0% - 100%.

high power factor: ≥95%

Low harmonic, reduce pollution to power grid

Saving energy about 20%

One power can supply two or multiple furnaces at the same time

Parallel power supply:

The parallel power supply adjusts the power through the rectifier. The variable frequency power has lower technical requirements for components and the cost of components is lower. So, manufacturer can reduce the cost of production. After years of use and development, Parallel power supply has stable performance with favorable price, which is suitable for low investment and the initial stage of the user.

Wide application range

mature technology

simple maintenance

good cost performance

Advanced options:

The variable frequency power can choose KGPS power or IGBT power. KGPS power uses SCR (silicon controlled) as inverter component. IGBT power uses IGBT (Insulated Gate Bipolar Transistor) as inverter component.

KGPS power: The advantages of this kind of power supply are mature technology, reliable quality, cheap price, the disadvantage is that the electrical efficiency is 10-20 percentage points lower than IGBT medium frequency power supply.

IGBT power: The advantage is that the electric efficiency is high, generally up to 90% or more. Therefore, the power saving ratio of silicon controlled power supply is 10-20 percentage points.

Water inspection system: Can detect the water temperature of multiple waterways,such as electric furnace(induction coil)water temperature ,SCR(IGBT)water temperature,reactor water temperature.Through this device can avoid components duet o high water temperature adn burn damage.

Remote consultation: Data retention and analysis are carried out on the operation state of the intermediate frequency furnace system through the "Internet of things" in the "headquarters of the company" to realize the remote diagnosis function. When there is a failure and shutdown, it can be dealt with in the first time.

Data collection and adjustment: directly collect voltage, current, frequency and other electrical parameters of each link, display and save in real time, customers can realize remote control operation through remote control cabinet.

Steel shell furnace body:

The furnace body of induction furnace is made of heat-resistant steel H steel, and the furnace shell of frame steel structure is made of reinforced steel plate. Compared with the traditional drum type, it is easier to maintain, and good ventilation is conducive to heat dissipation.

The magnetic shielding layer adopts oriented magnetic yoke with less heat, suitable for medium frequency furnace magnetic field, magnetic yoke adopts ultrathin silicon steel sheet, close to the inductor, forming a shielding layer to prevent magnetic field leakage, covering more than 75%.

Induction coil is made of thick-walled oxygen-free extruded copper tube with multi-layer insulation treatment, high strength and large current load.

The furnace body is equipped with cylinder driving safety guardrail to improve the safety of operation and prevent people from falling into the furnace pit and other accidents.

The installation of cyclone dust cover conforms to national environmental protection policy. Cyclone dust cover is connected with furnace mouth, dust removal pipe (connected with dust removal equipment), closed and efficient dust removal.

durable and safe

energy saving about 5%

tilting system can choose hydraulic or reducer

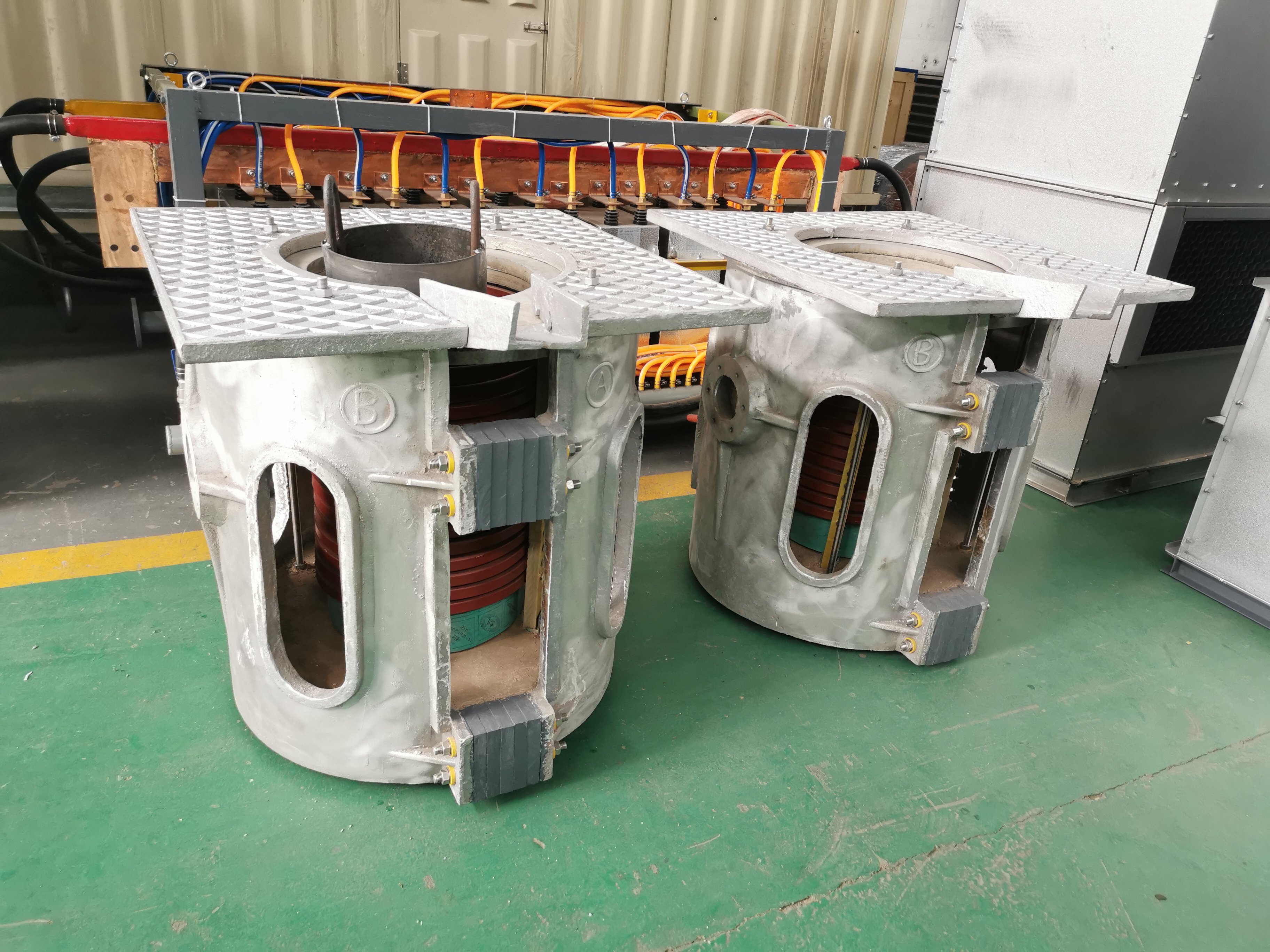

Aluminum shell furnace body:

Aluminum alloy furnace body, sensor outer layer wrapped with refractory cement, protection sensor, more durable, not easy to wear furnace. There is insulation board between the upper layer of inductor and asbestos board as support protection, asbestos board is not easy to break and crack, reduce loss.

Induction coil is made of thick-walled oxygen-free extruded copper tube with multi-layer insulation treatment, high strength and large current load. Inductor adopts A44 high strength and high refractoriness protective mortar casting as a whole, high refractoriness and good strength. Smooth surface, no ash. Induction coil is made of thick-walled oxygen-free extruded copper tube with multi-layer insulation treatment, high strength and large current load.

simple maintenance

good cost performance

Advanced options:

Cyclone dust hood:The installation of cyclone dust cover conforms to national environmental protection policy. Cyclone dust cover is connected with furnace mouth, dust removal pipe (connected with dust removal equipment), closed and efficient dust removal.

Furnace leakage alarm: By detecting current changes, the furnace body is provided with extremely reliable leakage furnace and any grounding fault all-round rapid protection. The detection system has the early warning function, when the furnace lining thinned to a certain extent, it will make the alarm light alarm in advance, remind the user to pay attention to the life of the furnace lining is coming, predict in advance and achieve the purpose of safe production.

PLC temperature control system: Directly set the melting temperature,through the temperature measuring device to detect the real-time melting temperature ,the power will automatically increase or decrease.More accurate adn easier to control the temperature of furnace water,adn less oxidation burning loss,uniform metal composition.

Furnace lining ejector:This device can push out of the furnace lining automatically through the hydraulic cylinder, which is saving labor and time to improve working efficiency.